The Complete Solution

Automate expense tracking and reporting with EZTrack Expense.

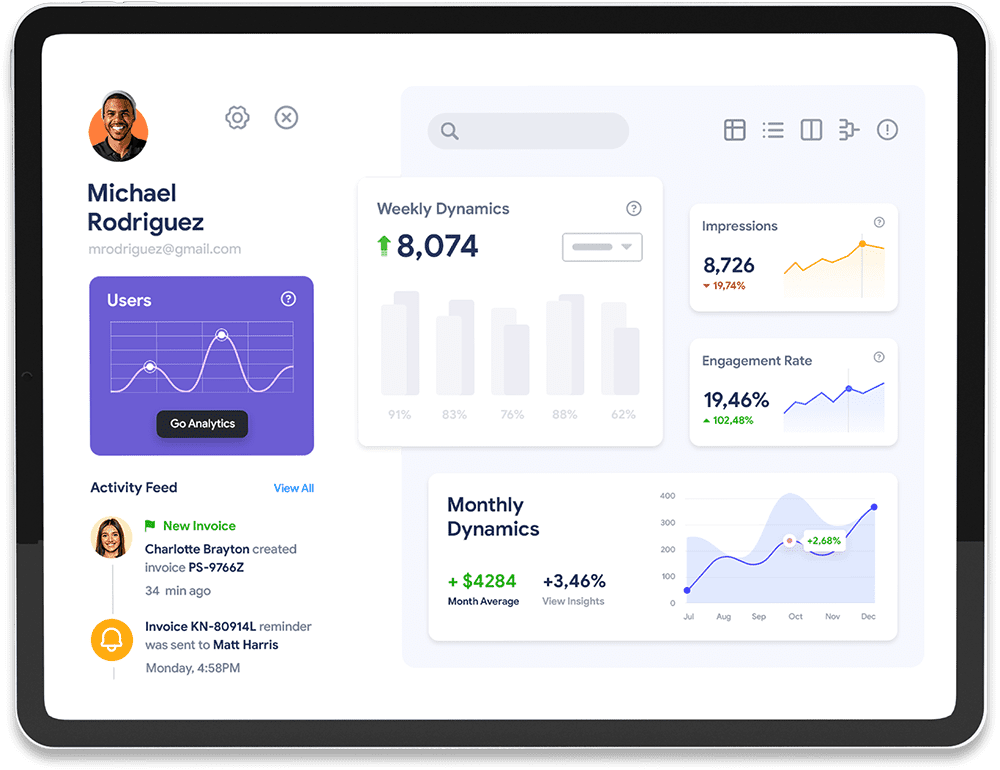

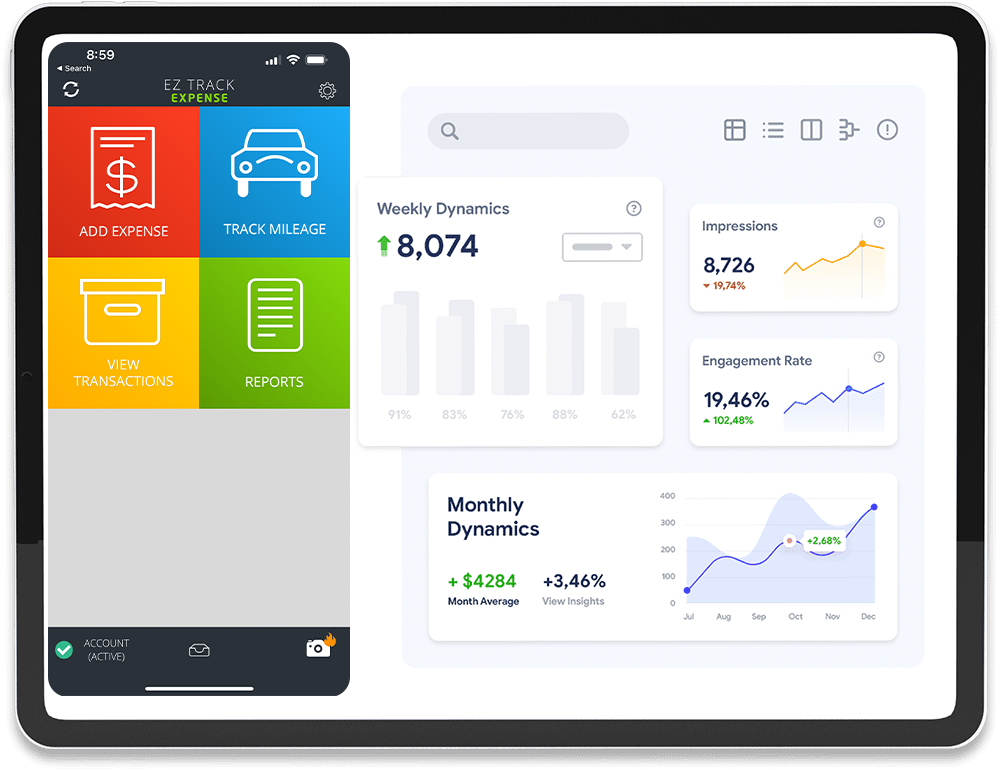

Mobile Application

Track mileage and turn receipts into expenses automatically while you are on the go with our iOS and Android apps.

Web Application

Auto create expenses by batch uploading receipt images or pdfs. Generate dynamic excel expense reports in seconds.

Automate Online Receipts

Send your email receipts to receipts@eztrackexpense.com and have them automatically converted to expenses.

A single tool for all your expense needs

Safely and securely track and manage expenses for personal, business, or multiple businesses with ease.

-

ALL of your expense data can always be exported in various formats json, excel, or csv for your convenience.

-

Your data is automatically encrypted before written to disk on our servers for maximum safety and peace of mind.

Cross-Platform

Use the EZ Track app from your iOS or Android device and access via the website any time.

Multiple Accounts

Easily track expenses and generate reports for personal, business, multiple businesses, or even as an employee.

Extremely Flexible

Export your data in json, excel, or csv format so that you always maintain control over your expense information.

Easy to Generate Reports

Generate reports in seconds so you have more time to do actual work.

Let EZ Track manage your expenses and reports

EZ Track uses artifical intelligence to extract information from your receipts automatically. It learns how you categorize receipts so that can do the heavy lifting for you. All you have to do is feed the app your receipts in png, jpg, pdf, or email format. EZ Track will take the information from your receipt and create an expense for you automatically. All you need to do is verify the information, assign it to the proper account, and attach it to an expense report.

-

Generating an expense report is as easy as tapping a button.

-

EZ Track will free up many hours of your time each month or year that you can put towards more important tasks.

Simplify. Optimize. Automate

Simplify your work life and free up your time for more important tasks. Let EZ Track automatically track your expenses and create reports for you.

Dynamic Excel Expense Reports

EZ Track generates dynamic excel expense reports that are suitable for your employer, book keeper, or accountant.

Stay in Control of your Data

Export your receipts, expenses, and reports in a variety of different formats so that your data is never held hostage.